HOME > DEMAGNETIZER

The "Demagnetization" is essential for manufacturing industry to manufacture products which using iron material. Nihon Denji Sokki Co., Ltd will propose demagnetizer having high performance and high reliability. Demagnetize products or objects magnetized due to various factors and it returns to a normal state.

Note: Pick out the typical equipment.

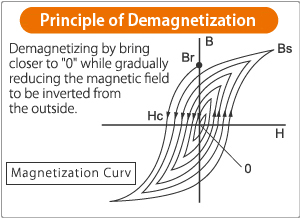

In general, iron is said to be magnetic substance. If magnetic field exists adjacent to a piece of iron. To eliminate these coercive force is generally called as "Demagnetization". It is necessary to demagnetize because magnetized magnetic materials cause various problems such as follows.

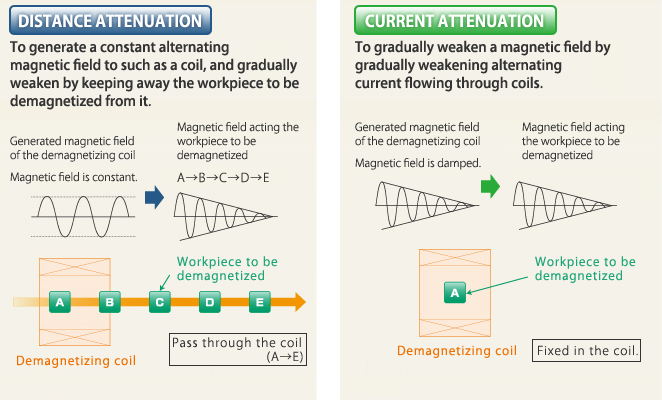

Demagnetization can be classified roughly into two types, "Distance Attenuation" and "Current Attenuation", by method for generating an alternating magnetic field.

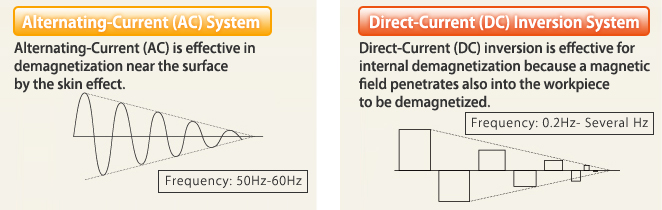

The electric current generating an alternating magnetic field is divided into "Alternating-Current (AC)" and "Direct-Current (DC) Inversion", and then select either the "Alternating-Current (AC) System" and "Direct-Current (DC) Inversion System" by the part to be demagnetized of workpiece.

Kind of Electric Current |

Alternating-Current (AC) System | |

|---|---|---|

Attenuation System |

Distance Attenuation: Tunnel type Air core type |

Distance Attenuation: Flat type |

Adaptive Demagnetizer |

|

|

Major Characteristics |

This product can be demagnetized easily by passing the objects into an air core coil which generates a constant alternating magnetic field using conveyor, etc. | This product generates a constant high alternating magnetic field by winding a coil around the iron core, and can be demagnetized also for complicated-shaped objects. |

| Object | Forged steels/Cast steels/ Steel bar, etc. | Machining process products (Small articles) |

Kind of Electric Current |

Alternating-Current (AC) System | |

|---|---|---|

Attenuation System |

Distance Attenuation: interpole type |

Current Attenuation |

Adaptive Demagnetizer |

|

|

Major Characteristics |

By arranging the iron cores above and below, a strong alternating magnetic field is generated between the iron cores. | This product attenuates the magnetic field by flowing Alternating-Current (AC) electric current into air-core coil and attenuating the electric current. It can be demagnetized without moving the object. |

| Object | Machining process products (Small articles)/ Sintered parts | Forged steels/ Cast steels/Steel bar, etc. |

Kind of Electric Current |

Capacitor System | Inverter System | Direct-Current (DC) Inversion System |

|---|---|---|---|

Attenuation System |

Current Attenuation | Distance Attenuation | Current Attenuation |

Adaptive Demagnetizer |

|

|

|

Major Characteristics |

This product can be demagnetized a high coercive force material by generating the strength resonance attenuation magnetic field by utilizing the resonance phenomenon between the oil capacitor and the coil. | This product produces a constant alternating magnetic field of low frequency by inverter control using IGBT. Therefore, it can be demagnetized to the inside of the object by passing it through the coil. | This product generates an alternating magnetic field very gentle by attenuating while reversing Direct-Current (DC) by the same principle as the Alternating-Current (AC) current attenuation. A magnetic field is permeated to the inside of the object and it enables strong demagnetizing. |

| Object | High coercive force material such as magnets | Steel bar/ Pipe/Long parts, etc. | Pipe/Long parts |