HOME > MAGNETIZER> Magnetic Field Press

Nihon Denji Sokki sees an opportunity for disruption in this industry, as the production of high-performance magnets is currently dominated by labor-intensive two-step die pressing systems. Our single step reduced isostatic pressure molds have already made significant progress in response to market trends, realizing better controllability and higher levels of automation over the whole process. Let us put our knowhow to work for you in finding cutting edge solutions for your use cases.

Our goals:

On Going Challenges

The universal adoption of single step die pressing technologies is being delayed by intellectual property issues, the poor quality of magnetic powders & their additives, and the inconsistency of the equipment available within the current installed base. The suitability of mold designs, or the capabilities of existing processes also must be considered when providing solutions for different use cases.

We have developed these automated systems for producing NdFeB sintered magnets, but our designs are flexible enough to serve a wide range of use cases involving the sintering of powdered materials: including compacting titanium alloys or ceramic powders. Magnets pressed in our isostatic rubber molds offer good alignment because pressure is applied equally over all degrees of freedom. Since the powder is then prevented from shifting with respect to the inner wall of the mold during the press, good alignment is obtained.

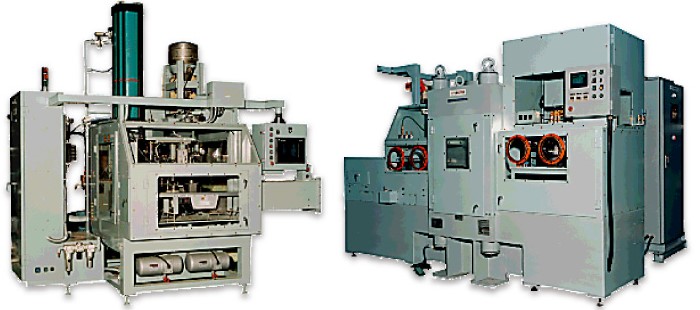

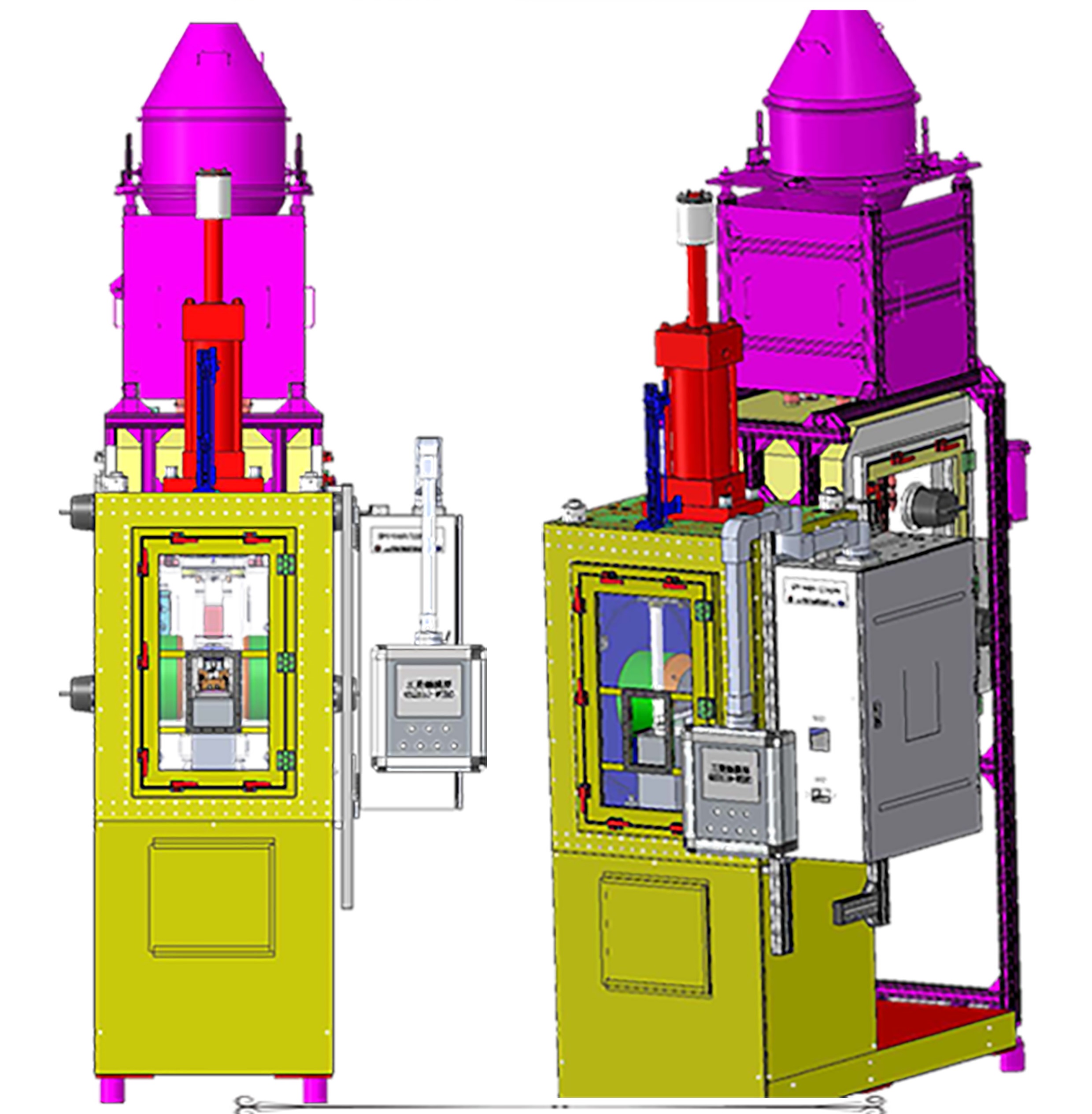

In a typical press system, there needs to be at least four stages; 1) fill -- magnetic powder injection into the mold, 2) pressing, 3) extraction, and 4) cleaning. The RIP Press shown in the figure utilizes a six-stage process that has been optimized for NdFeB magnet production. In addition to the four basic stages, a magnetic field orientation stage and one more cleaning stage are also required. Our presses have the option for an encoded turntable, which tracks the rubber molds as they move through each of these stages.

Advantages

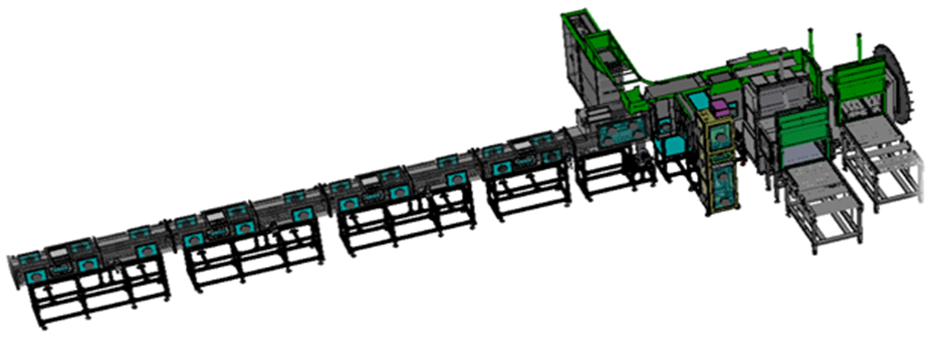

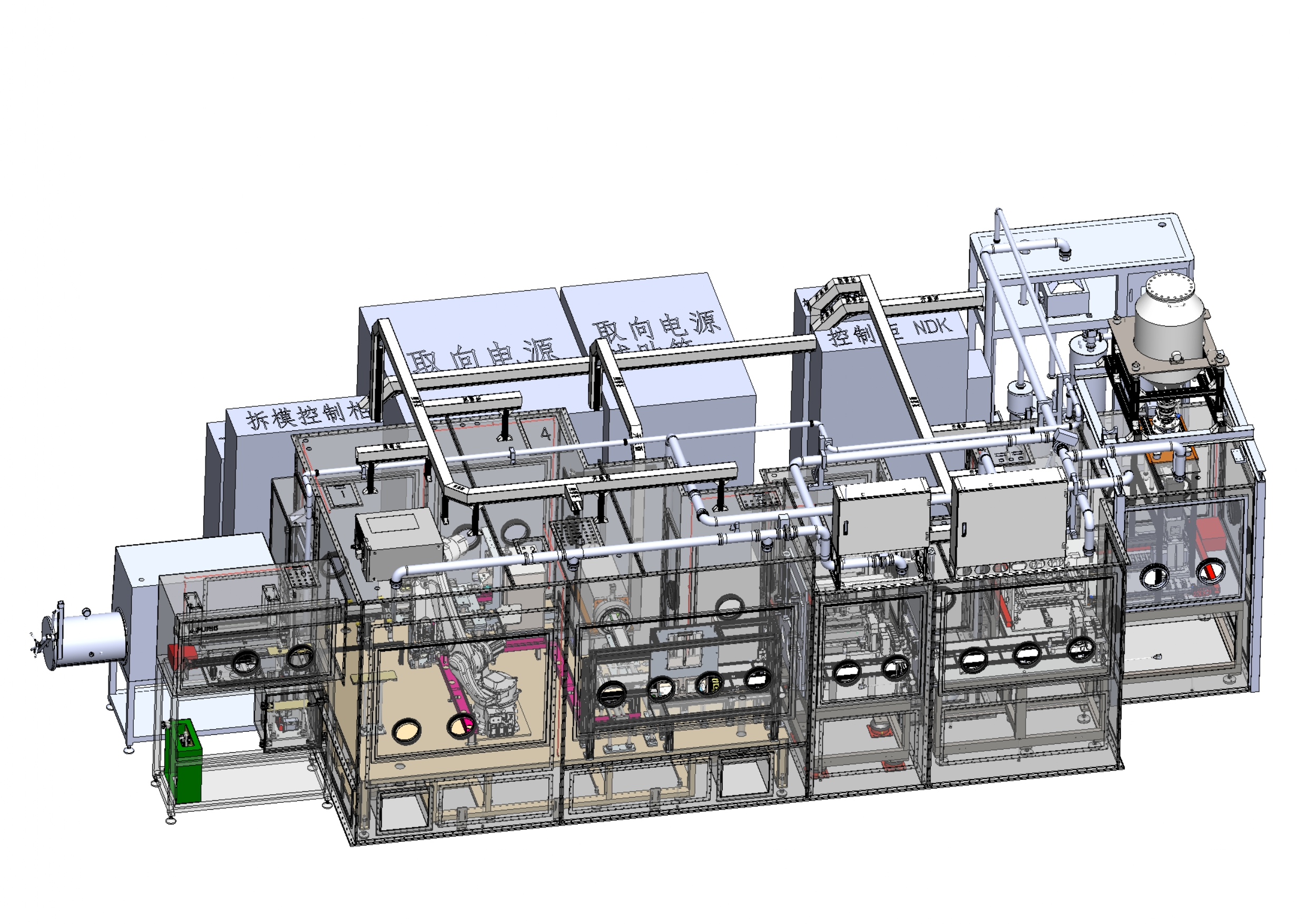

Our efforts have succeeded in the development of a fully automated sintering furnace for the mass production of rare earth element magnets (REE magnets). Our furnace is capable of sintering ferrous metal powders in a near oxygen-free environment (levels below 50 ppm). The press boasts of an automated material handling process and a mold stacking feature with a conveyor system that continuously feeds material to the furnace. This system is also fully traceable and compatible with computerized manufacturing execution systems (MES).

Features & Capabilities

Before the development of the automatic press, the ferric materials had to be weighed out manually and then fed into the mold by hand. While this method could produce magnet blocks with a density of 3.8 g/cm, results tended to be inconsistent due to affects attributed to human factors. The introduction of semi-automatic hydraulic presses (oil-based) did help increase densities to more than 4.5 g/cm; however, the press still suffered from poor efficiencies.

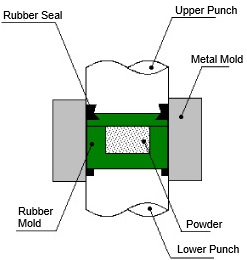

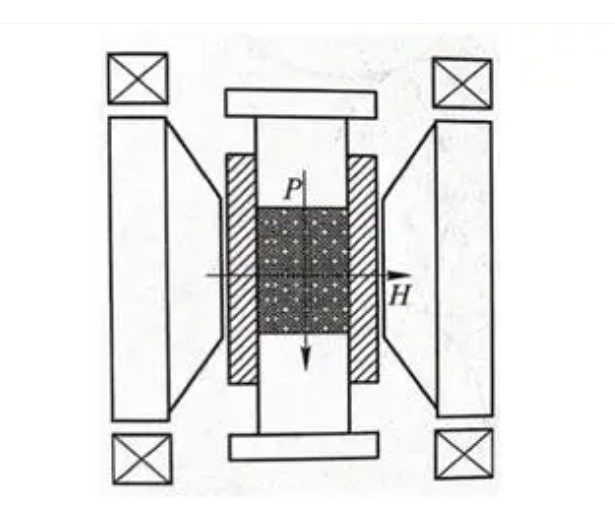

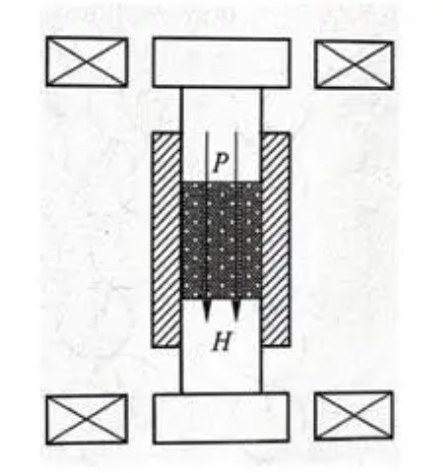

Nihon Denji Sokki developed its automatic RIP method to improve on results gained from the introduction of semi-automatic hydraulic presses. Our method is illustrated in the graph shown on the right. First the ferric materials are fed into the rubber mold’s cavity. Then as both the upper and lower punches work together to compress the powder within the rubber mold, the magnet block forms. Since the press acts in both vertical directions, the warping of the mold’s sides results in additional pressure from the horizontal direction.

Features:

| RIP | Hydraulic | Manual | |

|---|---|---|---|

| External Field | HF pulsed 6.5 T | 1600 kA/m | 800 kA/m |

| Block Density | 4.5 g/cm | 4.5 g/cm | 3.8 g/cm |

| Particle Size | 3.8 μm | 5 μm | 5 μm |

Thanks to the ability of this method to apply pressure equally in all directions, our isostatic rubber molds can offer you a high degree of pole alignment within your magnet blocks. The resultant isostatic pressure also prevents drift -- gaps forming between the mold’s inner wall and the powder within the mold’s cavity -- which has been observed in other methods.

Since our rubber isostatic presses can form magnets from powders using either hydraulic or mechanical methods. Our custom designs have been gaining popularity worldwide.

We can offer you bespoke systems aimed at research into magnet materials or equipment used for validating your production processes. While most magnetic press makers typically offer their presses and magnetizers separately, we integrate both into a complete system. Therefore, we will need to consider your use case when determining the design of your system in order to match the requirements of your press with the spec for the field alignment equipment.

Features:

Gelcasting, a ceramic forming process, was developed in the early 1990s at Oak Ridge National Laboratory by Prof. M. A. Janney. His method uses a mixture of organic monomers dissolved in solvents in which metals are suspended to form a low viscosity slurry (a concentrated suspension) which is then injected into a mold. This allows us to produce magnetic blocks with complex shapes. As this process has advanced from the laboratory to mass production, it has attracted interest from industrial customers thanks to its simplicity.

Our molds are able to use Gelcasting methods to form neodymium magnets. First, ferric neodymium powders must be suspended in an organic mixture to form a slurry which can then be injected into our molds. During magnetization, monomers within the slurry undergo polymerization forming a lattice structure with aligned magnetic regions (poles). Once this gel has been sintered, the lattice forms into a dense magnetic block.

To compress the gel in the mold, the press uses punches that must move simultaneously in a fixed direction but at different speeds with respect to the mold’s cavity. This process is controlled by software to achieve the optimal compression required for the desired uniformity. The gel’s density at the top, middle and bottom of the mold must of course remain constant.

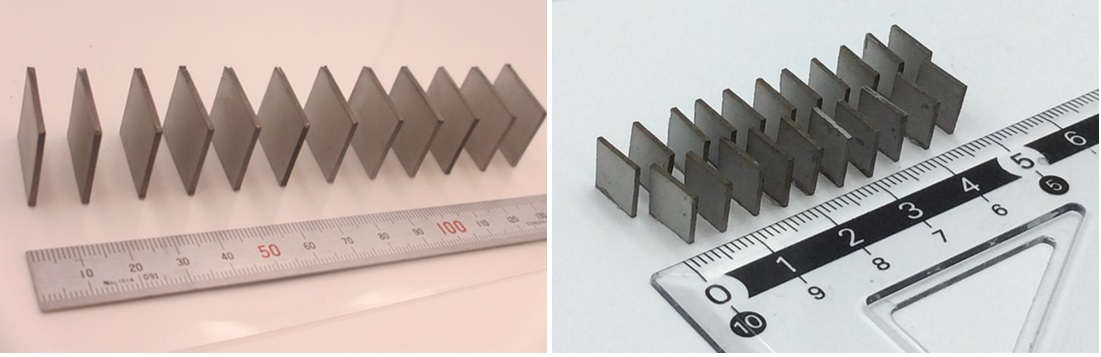

Free-floating compression ensures that we obtain consistent quality when producing neodymium magnets. Examples of the resultant blocks form by this method are shown in the photos.

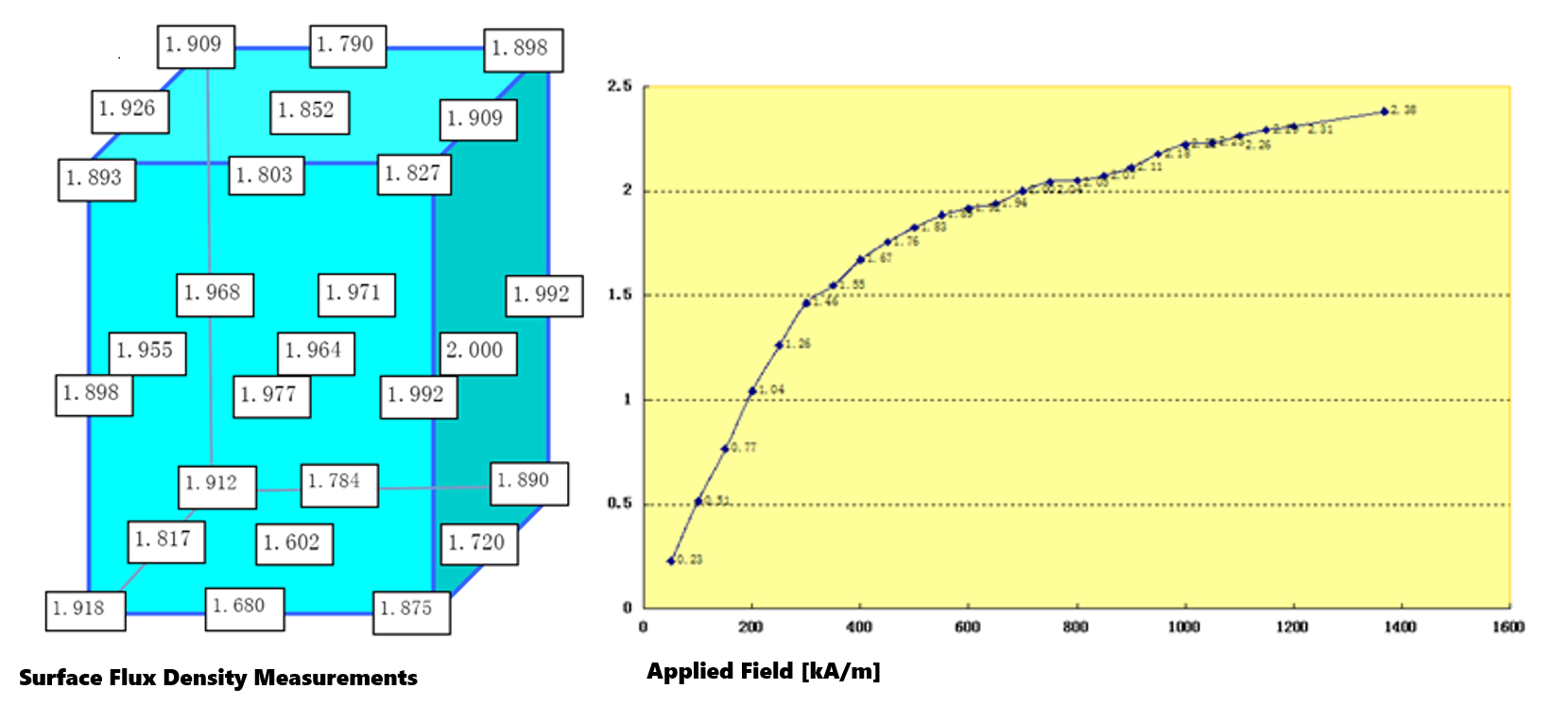

We have also improved the uniformity of the external alignment field that must be applied to the Gelcasting slurries. Our current technologies allow us to maintain field strengths up to 2.3 Tesla within the molds. At these levels we can guarantee stable internal fields even under continuous operational conditions.

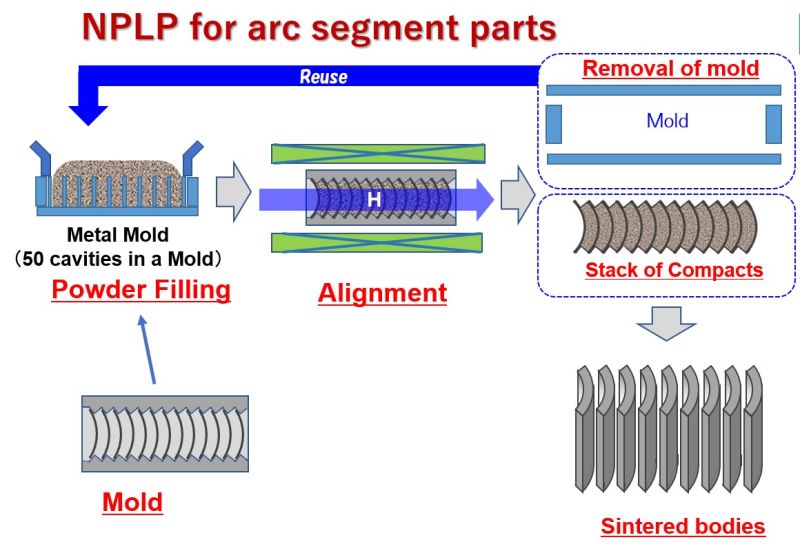

Nihon Denji Sokki is working with Dr. Masato Sagawa to commercialize his neodymium magnet molding system. This new pressless process (NPLP) is a near net shape (NNS) production technology that offers advantages over other sintered material processes when fabricating magnets with complex shapes for use in motors or other related equipment.

NPLP Magnets

On Going Research

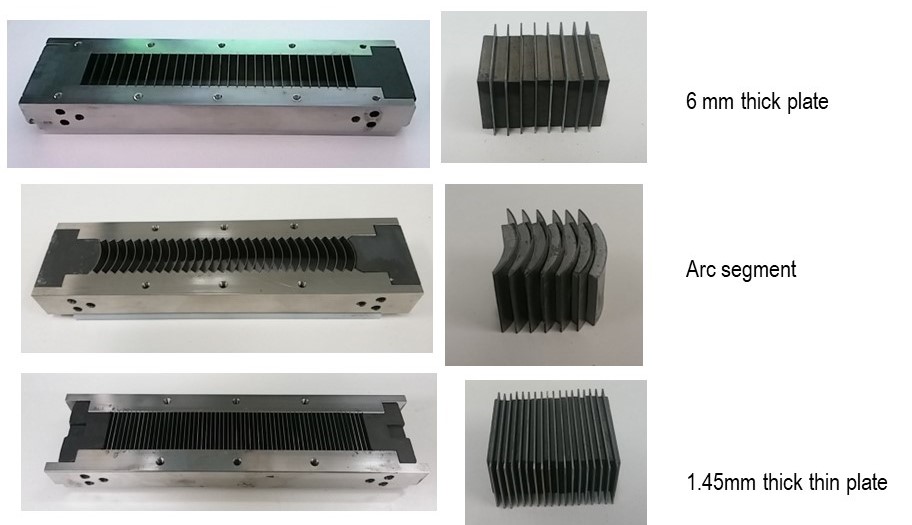

Reducing average particle diameters for the powders that may be pressed in the mold helps to mitigate issues with the scarcity and high price of rare earths by eliminating the need for dysprosium (Dy). While advances in traditional molding processes such as Axial Die Pressing (ADP) or Transverse Die Pressing (TDP) have reduced average particle diameters down to 3.8 μm, these technologies seem to have reached their limit. NPLP is capable of pressing powders with diameters near 1 μm. This process also opens up opportunities for improving the coercivities of the resultant block magnets. While TDP methods offer coercivities between 1240 ~ 1600 kA/m, our ongoing research into NPLP hopes to achieve coercivities approaching 2400 kA/m.

To sinter magnetic powders into the shapes that are as near as possible to the optimal block magnet designs for obtaining the best motor efficiencies, the uniformity of the powder packing, while the mold is being filled, is critical. Here is where NPLP enjoys an advantage over other methods thanks to its use of long narrow molds. This new method can achieve a fill factor of 3.5 g/cc which yields some of the most highly packed magnets – yielding densities of 7.52 g/cc.

In order to achieve good results using ultrafine powder -- diameters of 1.1 μm, the mold is set into a closed environment with an oxygen content lower than 0.0001%. Molds are filled to densities between 3.2-3.6 g/cm using an air tapping process (AT process). The powders within the molds are then sintered while a pulsed external field of 5 Tesla is applied.

Note: When producing magnets, the data shows coercivity and grain sizes are inversely correlated. TDP methods use powders with average grain diameter distributions centering on 5 μm, which yields blocks with typical coercivities of about 1040 kA/m. Moreover, older pressless process methods, which are capable of processing powders with average grain diameters of 1.2 μm, can achieve coercivities of 1600 kA /m.

Typical Results for NPLP

Magnet Block Measurements:

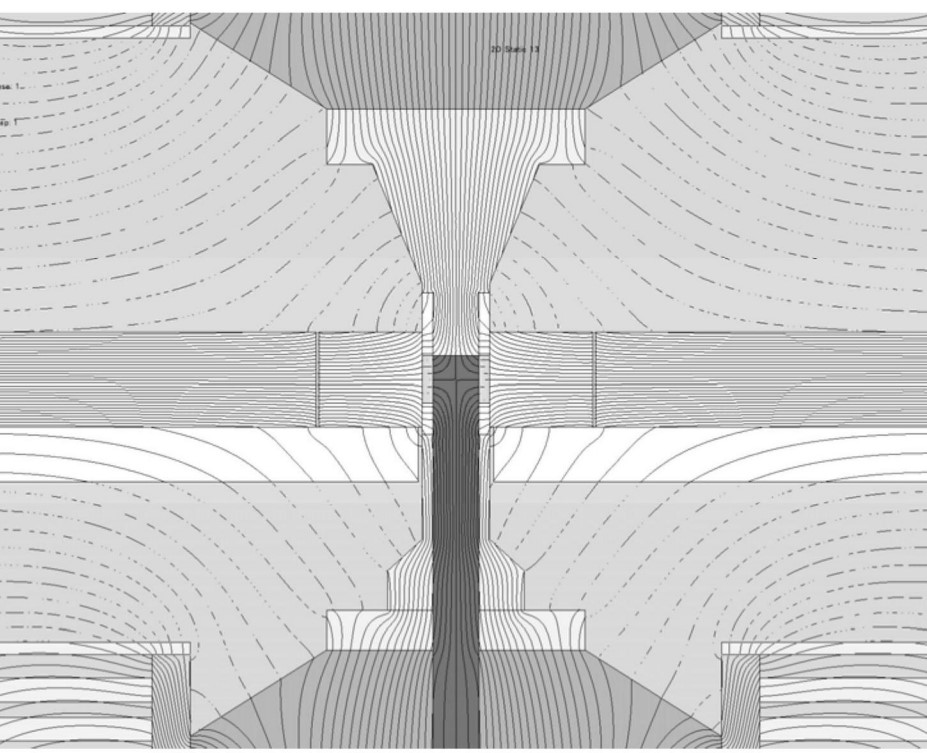

The improved coercivity for neodymium magnets offered by NPLP is due in no small part to the ability of existing pressless processes to handle powders with finer particle size distributions than those used in standard TDP methods. However, magnets resulting from these older processes often show less than ideal internal dipole alignment due to the tendency for the off-axis fields to grow within their molds while the powder is being sintered. By using long narrow molds with divides placed a fixed intervals along their length, the NPLP method allows us to successfully regulate the magnetic flux as it flows through each sectioned-off region of the mold. Since NPLP only requires a single mold, we can achieve a significant cost reduction.

Examples of NPLP molds are shown in the photos.

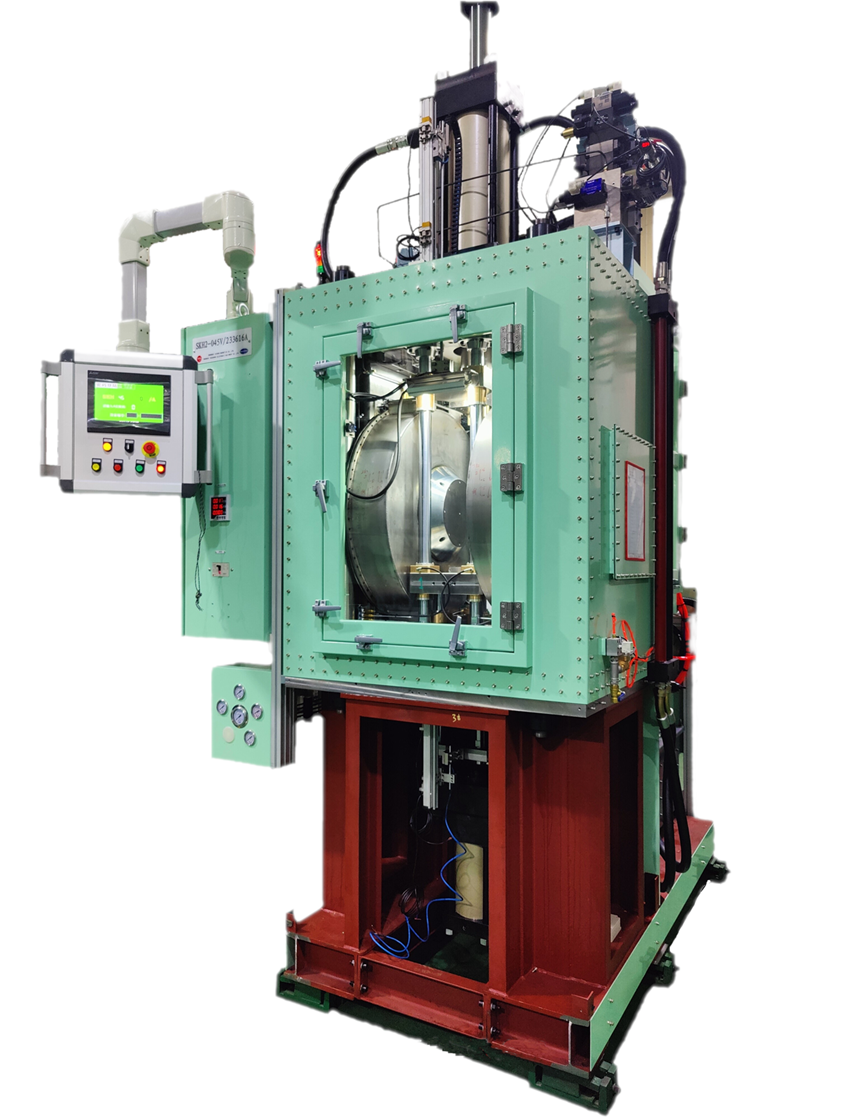

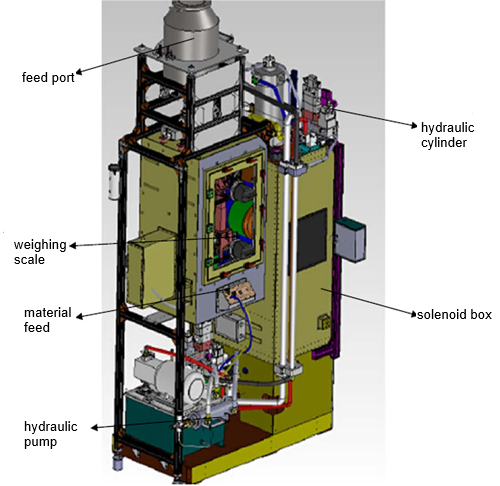

To guarantee the precision of our magnet presses we have adopted a hydraulic system with a dual compression / dual flow control design. All of the hydraulics are built into a unified chassis along with the press’s frame which gives the device a low center of gravity along with the added benefit of a compact footprint that saves factory floor space. Since dual compressions systems are simple and straightforward, we were able to minimize the number of complex parts and thereby increase the overall operational reliability.

Our precision compression method is based on a four-cylinder setup with two upper and two lower compression pistons. These cylinders are set into a frame with tight tolerances to hold the mold firmly in place while the external field is being applied. Once the magnetization has been completed, the hydraulics can then be toggled automatically to release the mold. This results in a single-step process that saves both on investment and labor costs.

All of our magnetic presses operate under precise numerical control provided by an integrated programmable logic controller (PLC). Users can access the PLC via a built-in touch screen interface. By providing this high degree of automation, our systems can reduce material waste during production which results in reduced resource costs and better sustainability.

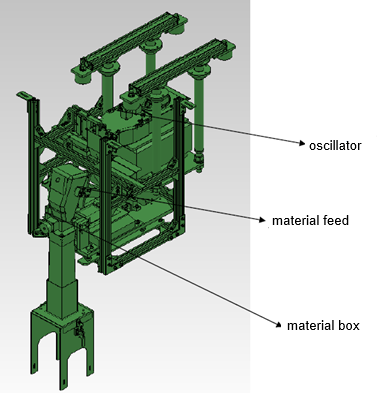

We have developed our fully automatic filling system to address customer concerns involving the weighing and manual feeding of magnetic material into the press. By automating this process, we were able to create a totally closed system where powder is weighed and fed right into molds without the need for any worker inputs. This ensures better consistency for each mold fill. Also, the fully enclosed production environment limits the risk of dust contamination to under 100 ppm, improving worker safety.

The feeding system consists of an electromagnetic oscillator which precisely controls the feed of the powder, an electronic scale which accurately weighs material, and a catch box which adds material evenly. This ensures that the gram weight of the added material is within the specified range and monitored automatically by the systems software.

Automatic Material Outfeed and Stacking

Once the magnetization process has finished, a robotic system removes the magnet blocks from the top of the mold cavity and places them on a conveyor belt, transporting them to storage for stacking. This completes the closed loop process and ensures that quality is maintained./p>

Oxygen Control Technology (OCT)

While the permanent magnet motors segment of the electric vehicle market has been witnessing steady growth, low yield issues due to sintered magnet’s tendency to crack have proven to be a major obstacle. However, cracking can be reduced by leveraging material matching techniques at the grain boundaries. Ratios of 2:14:1 have been found to be optimal.

The price of rare earths has been rising. To manufacture high-performance S-NdFeB magnets at a low-cost, manufacturers need to keep the total content of rare earth (RE) elements under 31.5%. Here, the development of oxygen control technology (OCT) makes a major difference.

OCT makes magnetic materials become less susceptible to oxidation, resulting in more stable and consistent overall performance. This means your presses will be better able to produce blocks with good mechanical properties.

Radial and Multipolar Field Alignment

To align the internal magnetic poles, external fields may be applied by the press to the rare-earth powders while the blocks are being sintered. First the mold needs to be filled with the magnetic powder, set in the press, and then sealed to create a nitrogen environment. Next you may select from a variety of highly efficient magnetic circuits capable of generating magnetic fields in the required shapes that will be suitable to perform the desired alignment. These fields may be in the transverse, longitudinal, or radial directions.

We offer three types of presses that can magnetize magnets in different directions:

1)Transverse Direction Pressing (TDP)

2)Axial Direction Pressing (ADP)

3)Radiative Direction Pressing (RDP)

Our industrial magnet presses use a timed, floating-fill method that is run by a programmable logic controller (PLC). This system ensures a uniform fill rate that minimizes any shrinkage on the sintered magnet blocks. This prevents any deformation from occurring.

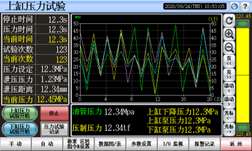

While the magnet presses are running through their compression cycle, hydraulic pressures and flow rates must be monitored and controlled precisely. This function is done by our PLC System, which adjusts the pressure at the valves automatically based on feedback obtained throughout the pressing process.

This level of control allows us to use high-precision molds -- gaps of 25 μm single-side. Better mold accuracy helps eliminate issues that lead to powder leakage, which not only wastes material but also leaves traces on the magnet blocks called flash. Since blocks showing flash traces will need to be reworked by the operators, the ability to eliminate flash results in savings not only in time but also labor costs. These leakage countermeasures also protect the production environment from dust contamination.

Pump Systems Controls: Variable Displacement, Electro-hydraulic, and Closed-loop

| Variable Displacement | Hydraulic Servo Values | Closed-loop Servo Values | |

| Upper Cylinder | |||

| stroke length | 350 | 350 | 350 |

| running speed | 0-140mm/s *Adjustable | 0-140mm/s *Adjustable | 0-140mm/s *Adjustable |

| Lower Cylinder | |||

| stroke length | 140/180 | 140/180 | 140/180 |

| running speed | 0-80mm/s *Adjustable | 0-80mm/s *Adjustable | 0-80mm/s *Adjustable |

| Specified Feild | 45T/63T | 45T/63T | 45T/63T |

| Accuracy | |||

| magnetic scale | 0.1/0.01 mm | 0.01 mm | 0.01 mm |

| Knock Pin | 0.1/0.05/0.01mm | 0.05mm | 0.01mm |

| Pole Diameters | 290/360/500 mm | 290/360/500 mm | 290/360/500 mm |

| Convergence Diameter | 200/250/350 mm | 200/250/350 mm | 200/250/350 mm |

| Field strength | 1.3-1.5 T or more (by 152-202) | 1.3-1.5 T or more (by 152-202) | 1.3-1.5 T or more (by 152-202) |

| Magnetizing Current | 800-1000A | 800-1000A | 800-1000A |

| Field Pluse | within 1S each | within 15 each | within 15 each |

| Water cooling | Generate magnetic field without weakening 24/7 | Generate magnetic field without weakening 24/7 | Generate magnetic field without weakening 24/7 |

| Hydraulic Pressure | 21mPa | 21mPa | 21mPa |

| Motor power | 11KW 3 phase asynchronous motor | 12.5KW Servo motor*2 | 7.5KW Mitsubishi servo motor*2 |

| Hydraulic control | Proportional valve control | Servo controlling pressure snd speed | Closed-loop servo control |

| Pressure system | Variable displacement pump proportional valve floating suppression | Double servo floating suppression | Closed-loop double servo floating suppression |

| Pressure Accuracy | 0.2mPa | 0.1mPa | 0.01mPa |

| Guid structure | 8 poles/12 poles | 8 poles/12 poles | 8 poles/12 poles |

| Mould Release | Pressure Relief/Air/Pressure feedback | Pressure Relief/Air/Pressure feedback | Pressure Relief/Air/Pressure feedback |

| Release Pressurize | 0.5T | 0.1T | 0.01 |

| Feed | Diameter 100 standard interface | Diameter 100 standard interface | Diameter 100 standard interface |

| Weighting | Imported load cell / imported digital scale | Imported load cell / imported digital scale | Imported load cell / imported digital scale |

| Weighting Accuracy | 0.5g/1g | 0.5g/1g | 0.5g/1g |

| Material Refill | Floating alternating refilling, repeat time adjustable | Floating alternating refilling, repeat time adjustable | Floating alternating refilling, repeat time adjustable |

| Pitch | 25-45 | 25-45 | 25-45 |

| Hermeticity | maintain the chamber pressure at 0.5kpa over 1h after cutting off the air | maintain the chamber pressure at 0.5kpa over 1h after cutting off the air | maintain the chamber pressure at 0.5kpa over 1h after cutting off the air |

| Total weight | 11T-24T | 11T-24T | 11T-24T |

| Material pickup | Automatic code wheel of 1 to 1, 2 to 1 or interconnection | Automatic code wheel of 1 to 1, 2 to 1 or interconnection | Automatic code wheel of 1 to 1, 2 to 1 or interconnection |

The PLC must ensure that the coil is always working at a constant temperature. This is accomplished by balancing the magnetizer's power supply and the coil's cooling system. Controlling the temperature not only stabilizes the field but also greatly reduces costs due to electrical consumption.

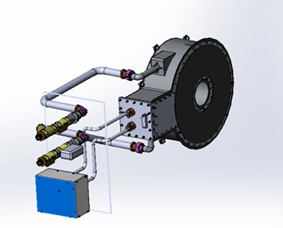

The coil assembly, including its built-in cooling system, is shown below. When the temperature is not controlled properly such that the coil's temperature increases, the field strength will drop and the quality of the magnetic blocks will be affected.

Our PLC system has a built-in communication module that allows you to interface our presses with your factory's network to monitor its operation remotely over the Internet. The PLC has a touch screen interface for easy setup. It is convenient and offers simple operation and quick installation.